Emitec Technologies GmbH

Hauptstraße 128,

53797 Lohmar, Germany

Phone: +49 2246 109 0

contact.emitec(at)emitec.com

Emitec Technologies GmbH

Hauptstraße 128,

53797 Lohmar, Germany

Phone: +49 2246 109 0

contact.emitec(at)emitec.com

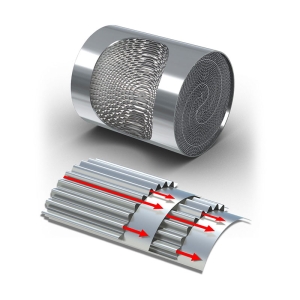

Metal substrate (METALIT®) with Perforated Structure (PE-Design ®) for catalytic converter.

Metal substrate (METALIT®) with Perforated Structure (PE-Design ®) for catalytic converter.

METALIT® – TS Design®

METALIT® – TS Design®

METALIT® with Asymmetrical Contour

METALIT® – with thin wall Mantle

METALIT® – without Mantle